Joining Technology

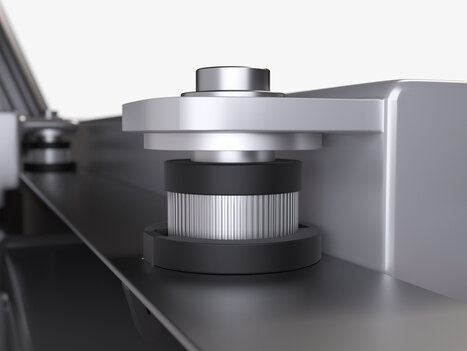

With our WITOL division, we offer innovative fasteners for a wide range of applications. WITOL stands for WITTE Tolerance Compensation.

WITOL was born from the vision of developing innovative tolerance compensation solutions for our automotive customers. Since the invention of the first tolerance compensation element, the division has specialized in solving complex challenges in the automotive industry with precise and adaptable fasteners.

Our tolerance compensation systems compensate for precise component tolerances, reduce assembly times and ensure reproducible quality. As a division of WITTE Automotive GmbH, we complement the product portfolio with customized solutions that guarantee maximum stability and production quality.

The WITOL system enables fast and precise compensation of component tolerances during assembly: by rotating the driven screw, the WITOL system automatically and simultaneously compensates for tolerances during the fastening process. As a result, a tension-free and reproducible screw connection is reliably produced. This leads to a significant optimization of production processes and a reduction in overall costs.

Product advantages:

WITOL offers a wide range of fastening solutions optimized for different applications. Our systems are customized to the individual requirements of each customer to ensure optimal results. Whether for exterior door handles, tailgate modules, front end or electric mobility - we develop the right solution for your specific needs.

Find out more about our proven WITOL tolerance compensation elements here:

Good to know:

The first WITOL was once sketched spontaneously on a napkin at the airport by the then technical managing director after he returned from a customer visit and was confronted with a tolerance problem there once again.