Test center

The WITTE test centers include five closely networked test laboratories in Velbert (DE), Nejdek (CZ), Ruse (BG) , Taicang (CN) and Pune (IN). This global presence and cooperation enables us to guarantee the highest quality standards and fast response times. With our expertise and state-of-the-art technologies, we offer reliable testing and validation services for a wide range of requirements.

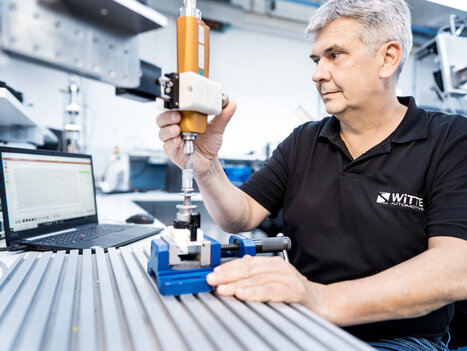

WITTE is characterized by a high degree of standardization in test fixtures and test equipment. Thanks to our in-house expertise, we can develop and design individual test fixtures that are optimally tailored to our customers' test requirements.

Focus of the test procedure

The test procedures focus on the validation and development-accompanying tests of our mechanical and mechatronic products. In addition, WITTE offers support for technical product issues and carries out regular requalification tests.

Functional tests

During functional tests, the basic functional parameters of the assemblies are checked. These tests include

- Stroke

- Power

- Torque

- Rotation angle

- Speed

The test setup is usually carried out in accordance with the product drawing, with particular attention paid to opening and closing paths, forces, switching points and other special features.

Strength tests

Strength tests focus on checking the strength parameters of the assemblies. Forces are applied that go beyond normal use in order to test functionality under extreme load conditions.

Durability tests

These tests simulate repeated use of the product in a specific temperature and humidity range to ensure long-term functionality. Special test benches are used for this purpose, which simulate real-life conditions.

Climate tests

In climate tests, the functionality of the product is tested under various environmental conditions, including:

- Hot climate conditions (up to 90°C)

- Tropical conditions (50°C / 90% humidity)

- Cold / arctic conditions (down to -40°C)

Corrosion tests

Corrosion tests simulate the effects of heat, moisture and salt on our products. These tests validate not only the corrosion resistance, but also the mechanical and electrical functionality after exposure to these elements.

Acustic tests

Acoustic tests are carried out both at component level and in complete vehicles in our drivable acoustics laboratory. These tests are essential to ensure that our products meet the required acoustic standards.

Safety-related tests and mechatronic validations

WITTE products are safety-relevant and must therefore meet the strictest strength requirements, such as those that occur in vehicle crashes. These tests are carried out in tensile-compression testing machines that exert forces of up to 50 kN (approx. 5000 kg) on the components.

In addition, highly complex mechatronic components that combine electronic circuits and comprehensive software with mechanical components are tested and validated. This includes functional testing of the software as well as the development and use of individual test benches by experienced specialists.

Advantages at a glance: